Popular demand is pushing more and more for green energy alternatives to oil and gas. As a province known for the latter, finding a way forward might be cause for an identity crisis. But if you think this oil stalwart of a province would be the last place to champion clean energy, think again. In fact, many of the brightest minds in oil and gas are turning their expertise toward the future of energy, and this is the case with Proton Technologies.

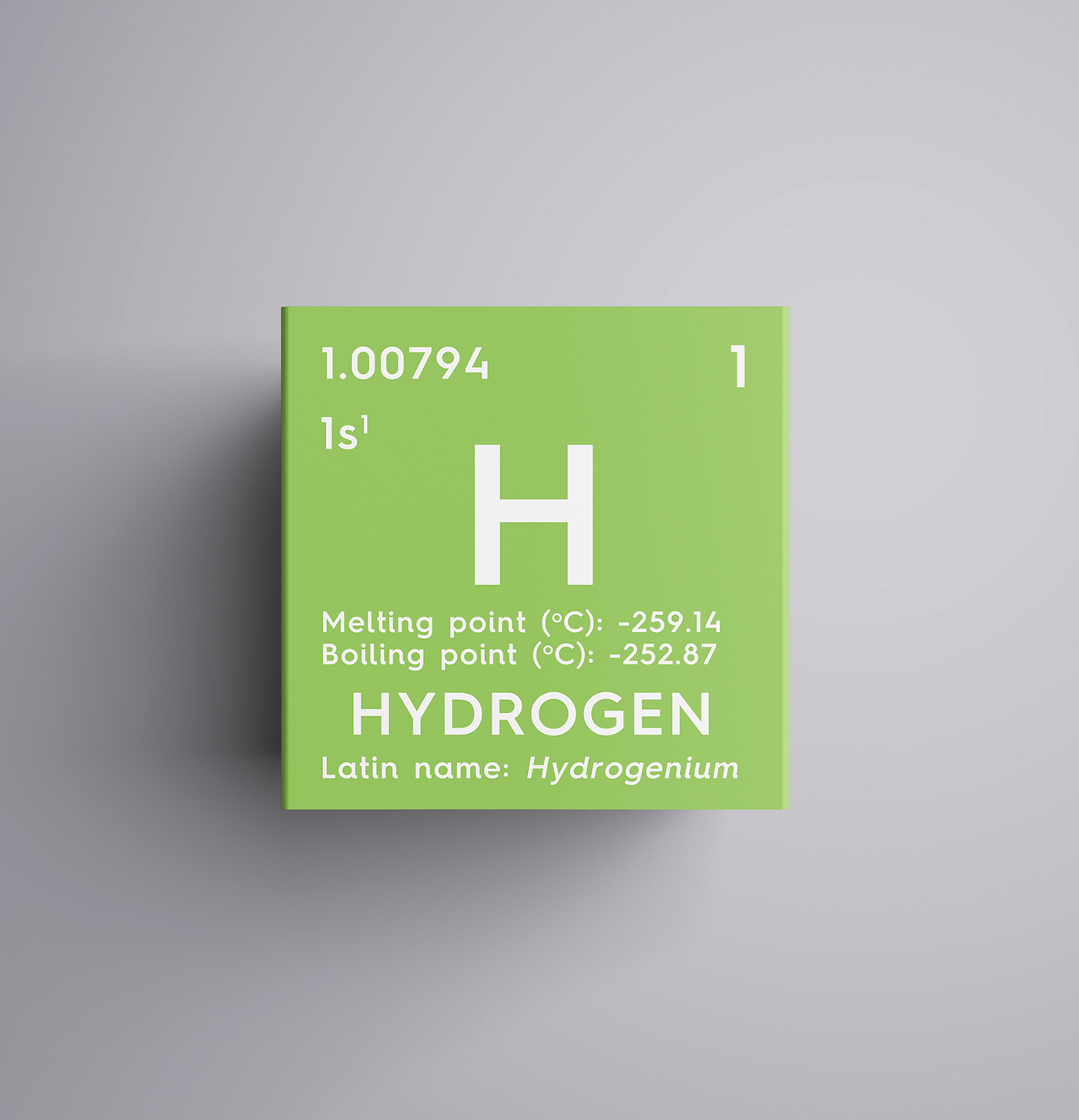

Proton is a Calgary-based energy company that’s bringing hydrogen into the clean-energy discussion after years of having this abundant resource largely ignored. Its patented technology allows for hydrogen (H) to be separated from water (H2O) and extracted from oil sands (or other hydrocarbon reservoirs such as gas or coal) while leaving carbon and other pollutants in the ground.

Grant Strem, the chairman and CEO of Proton, said he has always had a peripheral interest in hydrogen, even as he spent most of his career as a reservoir evaluator and research analyst in the oil fields. That interest is now top-of-mind, thanks in part to Dr. Ian Gates of the University of Calgary, Department of Chemical and Petroleum Engineering. Gates is also a co-founder of Proton, as well as co-inventor along with Jacky Wang, a research engineer in Gates’ research group at UCalgary.

Gates and Strem, who were friends before they partnered to start Proton, came up with the idea about the viability of hydrogen as a clean energy source together. In the course of collaboration, Gates referenced data from a 1980s oilsands study that showed if you inject oxygen into oil reservoirs — which are treasure troves of chemicals — you produce hydrogen. “When he mentioned that, I thought, ‘Wow, if we had a way to leave everything in the ground except for that hydrogen, boom! We’d have a clean energy business,’” Strem said.

In the past, the main problem with hydrogen as an energy source has been the cost of producing it. Pure hydrogen is rare, so it must be separated from other sources. Unsurprisingly, the most cost-effective way to produce hydrogen is the least green: steam methane reforming. Other processes that are green, like electrolysis (separating hydrogen from water using an electric current) are costly. “The missing ingredient in all of this has been low-cost hydrogen from clean sources,” Strem said.

Proton’s patented process involves injecting oxygen through pipes up to two kilometres underground, where it reacts with the oil in a process called in situ oxidation, which is normally used to heat the oil and help with its extraction. Above 300 degrees Celsius, it causes a number of reactions that rip the hydrocarbon apart into a bunch of trapped, synthetic gases, including hydrogen. It also rips apart the H2O in the oil sands. Strem said part of the challenge was finding the right membrane for their well that would filter everything else out and only let hydrogen pass through.

Alberta’s advantage in all this is its wealth of resources to access. Canada holds 10 per cent of the world’s oil — the third-largest oil reserve globally — and a large majority of that is in Alberta, according to National Resources Canada. Because Proton is only taking advantage of the reaction, they don’t necessarily need oil good enough for extraction either. On top of that, the province is equipped with an infrastructure meant for transporting masses of product in the form of pipes, Strem said. He adds that pipelines should be future-proofed by making them capable of transporting hydrogen. “If we did this right,” Gates said, “We could turn Alberta into the hydrogen capital of the world, with respect to production, given the resource we have here.”

For the foreseeable future, Proton is working up to trucking its hydrogen out in commercial loads from its reservoir in Saskatchewan. From there, the hydrogen might be used for supplementary purposes like upgrading fuels or blending with natural gas, before being used for hydrogen fuel cells in vehicles or to produce electricity energy in the form of heat or electricity.

Strem said you might even be able to fill your hydrogen fuel cell from home someday, but that future is a long way off. The most common hydrogen fuel-cell vehicle is the Toyota Mirai, which is only just coming to Canada now. You can count the hydrogen fueling stations between Vancouver and Quebec City on one hand.

“The world needs oil, that is definitely the case,” Gates said. “But does it need Alberta heavy oil and bitumen? That’s the one thing I wonder about. As this world moves and it starts to shift things and folks move to other fuels — electrification renewables and other things — where does Alberta play a role? I think we need to be thinking about what happens in 20 years. We could either wait and react then, or we could actually now say, ‘Well, we’re going to change the nature of this resource and how we value it, how we move forward with it, and do that right now.’”

More Calgary Energy Companies You Should Know About

Eavor

Eavor (pronounced “ever”) is an Alberta-based energy company looking to geothermal for a green approach to generating power. Eavor has developed a closed-loop system, called the “Eavor-Loop,” that works like a radiator, unlike most geothermal systems that require a drill or pump. Kilometres underground, lateral pipelines filled with a benign fluid are heated by the earth through conduction. The heated fluid rises above the cool fluid, which is pushed to the lowest point to repeat the process. This continuous circulation generates power. One advantage of this system of natural chemistry is it doesn’t rely on mechanical or power-driven pumps, and isn’t dependent on the elements like solar or wind.

Excitingly, Eavor completed a demonstration site near Rocky Mountain House, Alta., at the beginning of February, 2020. Its math was checked by a Dutch assessment team, and Eavor is now looking to explore commercial projects. It has already struck a partnership with the Carmacks Development Corporation (owned by the Little Salmon/Carmacks First Nation) in the Yukon to provide baseline power for upcoming development projects.

Carbon Credit Solutions

In 2007, the Alberta government passed legislation to regulate greenhouse gas emissions from large industrial emitters. It also developed a carbon market — essentially, a system that allows emitters to trade carbon credits or earn offset credits for good practices. For example, if an oil and gas company can prove it voluntarily reduced emissions, and it passes the guidelines set by the province, it may earn offset credits that can be sold on the market to another emitter.

Like any financial market, it’s a complicated business, and that’s where Carbon Credit Solutions comes in. The company uses proprietary software to quantify and verify carbon emissions for clients like farmers and oil and gas companies and converts them into marketable carbon credits. It also consults with different industries, helping develop ways to reduce their emissions. For example, it might help a farm realize the potential of no-till farming or help increase the utility efficiency of a residential building. The goal is to bridge the gap between environmental responsibility and economic prosperity.